联系姓名:金宝林

联系电话:13957676832

所在地区:浙江

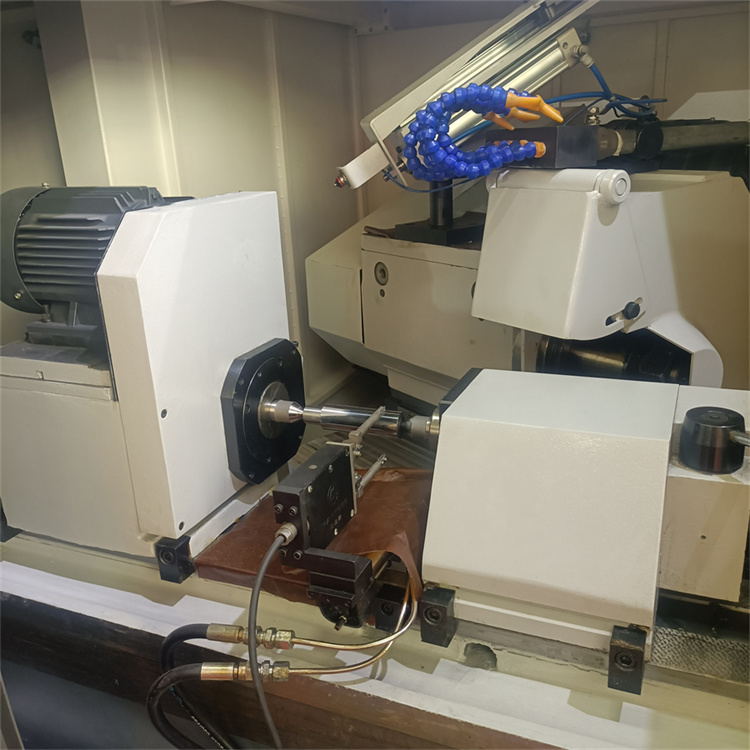

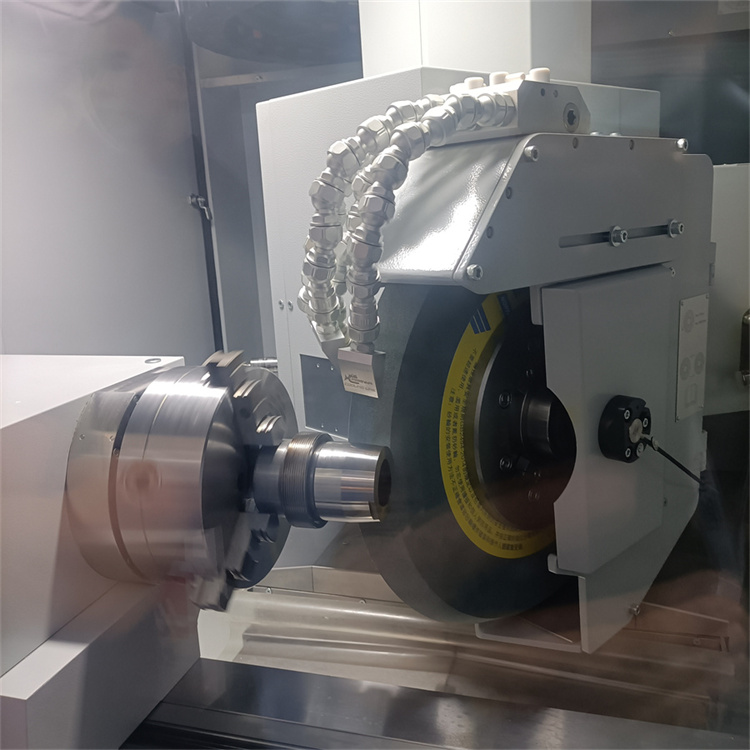

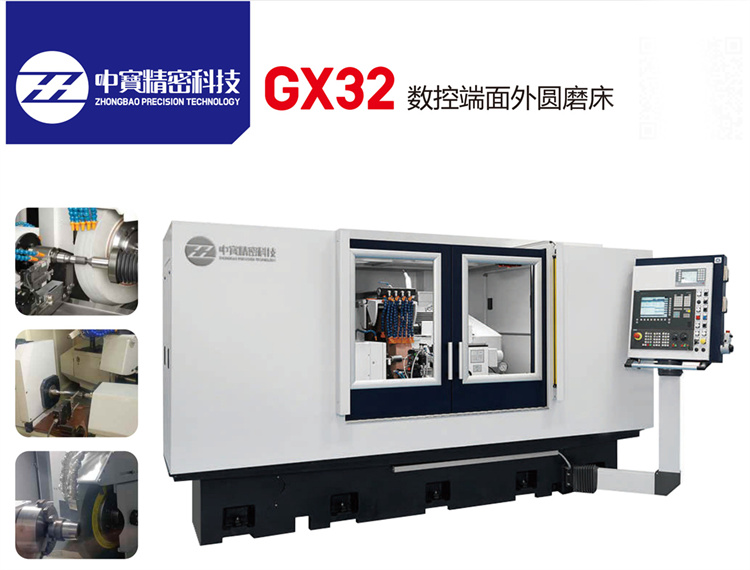

主营产品:数控外圆磨床、数控端面外圆磨床、数控复合磨床

提交后,商家将派专人为您服务

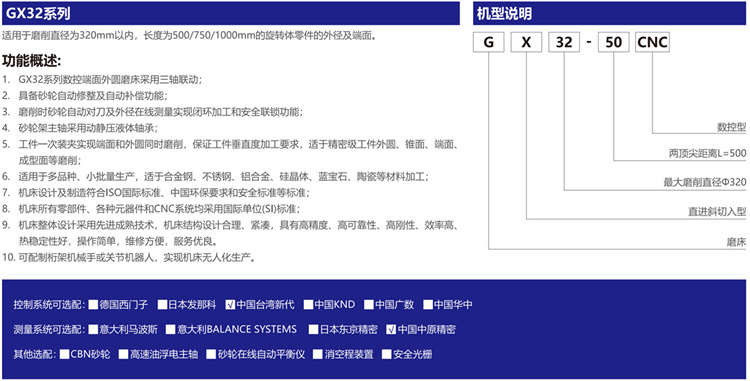

| 项目 | 单位 | GX32-50CNC | GX32-75CNC | GX20-100CNC | |

| 直进斜切型 | 直进斜切型 | 直进斜切型 | |||

| 加工能力 | 工作台zui大回转直径(Maximum turning diameter of the workbench) | Φ350mm | |||

| Processing capacity | 两顶心中心距离(Center distance between two apical centers) | 500mm | 750mm | 1000mm | |

| zui大磨削直径(maximum grinding diameter) | Φ320mm | ||||

| 中心高度(Center high) | 180mm | ||||

| 两顶心zui大荷重(Maximum load of two cores) | 150kg | ||||

| 砂轮尺寸 | 直径x宽度x内孔直径(Diameter x width x inner hole diameter) | 600x75x305mm | |||

| Grinding wheel size | 砂轮转数(Grinding wheel revolutions) | 1430/1910rpm | |||

| 砂轮线速度(Linear speed of grinding wheel) | 45/60m/s | ||||

| 砂轮架(X轴) | 快速进给速度(Rapid feed speed) | 12M/min | |||

| Grinding wheel holder (X-axis) | 进给角度(Feed angle) | 30° | |||

| zui小单位进给(Minimum unit feed) | 0.001mm | ||||

| 进给行程(Feed stroke) | 275mm | ||||

| 主轴头架(伺服)Spindle head rest (servo) | 顶心锥度(Apical taper) | MT5 | |||

| 主轴转速(Apical taper) | 20~600rpm | ||||

| 主轴型式(Spindle type) | 定心或活芯 | ||||

| 尾座(气浮) | 顶心锥度(Apical taper) | MT5 | |||

| Tailstock (air flotation) | 动作行程(Action stroke) | 60mm | |||

| 主轴型式(Spindle type) | 固定行程或可调行程 | ||||

| 工作台(Z轴) | 快速进给速度(Rapid feed speed) | 12M/min | |||

| Workbench (Z-axis) | 工作台行程(table stroke) | 550mm | 800mm | 1050mm | |

| zui小单位进给(Minimum unit feed) | 0.001mm | ||||

| 旋转角度(Rotation angle) | ±7° | ||||

| 马达motor | 砂轮主轴马达(Grinding wheel spindle motor) | 11KW | |||

| 主轴头架(伺服)马达(Spindle head rest (servo) motor) | 10Nm | ||||

| 砂轮架(X轴)(伺服)马达(Grinding wheel holder (X-axis) (servo) motor) | 18.6Nm | ||||

| 工作台(Z轴)(伺服)马达(Workbench (Z-axis) (servo) motor) | 18.6Nm | 28.4Nm | |||

| 磨削液泵(Grinding fluid pump) | 1.1KW | ||||

| 液压油泵(hydraulic pump) | 0.4KW | ||||

| 滑动面润滑泵(Sliding surface lubrication pump) | 0.06KW | ||||

| 砂轮轴润滑泵(Grinding wheel shaft lubrication pump) | 0.75KW | ||||

| 箱容积 | 磨削液箱(Grinding fluid tank) | 180L | |||

| Box volume | 液压油箱(Hydraulic oil tank ) | 20L | |||

| 砂轮轴润滑箱(Grinding wheel shaft lubrication box) | 100L | ||||

| 滑动面润滑箱(Sliding surface lubrication box) | 5L | ||||

| 机床精度 | 加工圆度(Processing roundness) | ≤0.001mm | ≤0.002mm | ||

| Machine tool accuracy | 尺寸一致性(Dimensional consistency) | ≤0.004mm | |||

| 表面粗糙度(Surface roughness) | Ra0.2um | ||||

| X轴重复定位精度(X-axis repeated positioning accuracy) | ≤0.0015mm | ||||

| Z轴重复定位精度(Z-axis repeated positioning accuracy) | ≤0.0025mm | ||||

| 执行标准(Executive standards) | JB/T9914-1999 | ||||

免责申明:本网页所展示的有关【GX32数控端面外圆磨床_磨床】的信息/图片/参数等由中商114的会员提供,由中商114会员自行对信息/图片/参数等的真实性、准确性和合法性负责,本平台(本网站)仅提供展示服务,请谨慎交易,因交易而产生的法律关系及法律纠纷由您自行协商解决,本平台(本网站)对此不承担任何责任。

友情提醒:建议您通过拨打厂家联系方式确认最终价格,并索要GX32数控端面外圆磨床_磨床样品确认产品质量。如GX32数控端面外圆磨床_磨床报价过低,可能为虚假信息,请确认GX32数控端面外圆磨床_磨床报价真实性,谨防上当受骗。